How to build cunstrution Steel rods and beams

Building with construction steel rods and beams involves several steps, from selecting the right materials to properly installing them in your structure. Here’s a step-by-step guide on how to use steel rods (TMT bars) and beams in construction:

1. Material Selection

- Steel Rods (TMT Bars): These are used to reinforce concrete in construction. Choose high-quality TMT (Thermo Mechanically Treated) bars with a minimum grade of Fe 500 or Fe 550, depending on the load requirements. These rods offer high strength, ductility, and corrosion resistance.

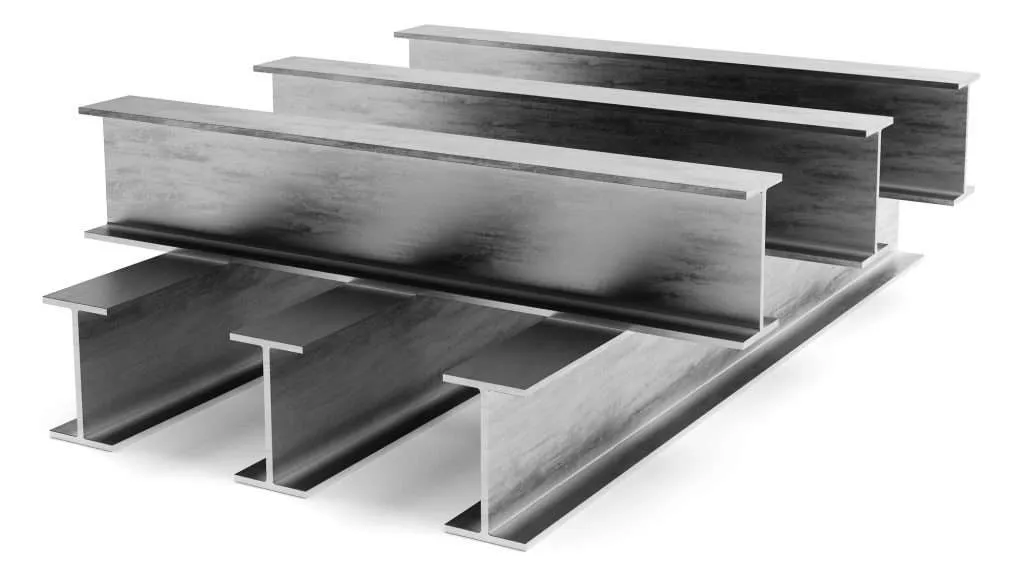

- Steel Beams: Used for providing structural support. Common types include:

- I-beams (H-beams): For heavy structural loads.

- Angle beams: For supporting corners and edges.

- Channel beams: For lighter support in floors and roofs.

2. Preparation and Planning

- Structural Design: Consult with a structural engineer to design the steel framework based on the load requirements and the type of building (residential, commercial, multi-story). The design should specify the size, number, and placement of steel rods and beams.

- Load Calculation: Proper calculation of load distribution ensures the building can handle its own weight (dead load) and external forces (live load, wind, seismic activity).

3. Cutting and Bending Steel Rods

- Cutting to Size: TMT bars are available in long lengths and need to be cut based on your construction needs. Use a steel cutter or rebar cutter to accurately cut rods.

- Bending: TMT bars are bent into required shapes using a bar bending machine to form stirrups, columns, or beam reinforcement cages. This allows them to fit into the formwork for columns, beams, and slabs.

- Stirrups: These are rings made from steel rods that hold the main reinforcement bars in place and prevent them from buckling.

4. Reinforcing with Steel Rods (Rebar)

- Columns: Place the vertical steel rods (main rebars) in the column framework and secure them with stirrups at regular intervals.

- Beams: The beams are reinforced by laying steel rods in the formwork. Typically, two or more rods are placed at the top and bottom of the beam, and they are held together by stirrups.

- Footing: Reinforce the foundation (footing) by placing the steel mesh inside the formwork. The rods must be arranged in a grid pattern and tied securely with binding wire.

- Tying the Rebar: Steel rods are tied together using binding wire at junction points to prevent them from shifting during concrete pouring.

5. Installing Steel Beams

- Laying Foundation Beams: Place steel beams in the foundation for heavy load-bearing walls or columns. These beams will carry the weight of the structure and transfer it to the ground.

- Positioning Beams: For larger structures, I-beams or H-beams are installed horizontally between columns to support floors or roofs. Ensure they are properly aligned and supported with temporary props or scaffolding.

- Connections: Beams are connected to columns using welded joints or bolted connections. Use proper welding techniques to ensure a strong bond and inspect the welds for quality.

6. Pouring Concrete

- Formwork: Before pouring concrete, a formwork (wood or steel) is created to mold the concrete around the steel reinforcement.

- Concrete Pouring: Pour concrete over the steel rods and beams, ensuring that all the steel is well covered. The concrete must be well-compacted to remove air pockets and properly bond with the steel.

- Curing: Allow the concrete to cure (harden) for a minimum of 7 to 28 days to reach its maximum strength.

7. Installation of Roof and Floor Beams

- Roof Beams: For multi-story buildings or houses with flat roofs, install steel beams to support the roof. In sloped roofs, lighter steel trusses may be used.

- Floor Beams: Steel beams are often installed to support floors in high-rise buildings. Ensure they are properly connected to the main framework and the load is evenly distributed.

8. Inspection and Testing

- Load Testing: After installation, ensure the structure is tested for load-bearing capacity. A structural engineer should inspect the steelwork to ensure it meets the required specifications.

- Safety Standards: Follow all local building codes and safety standards for steel construction to avoid structural issues or failures in the future.

9. Finishing

- Corrosion Protection: Apply anti-corrosion treatments or paint to steel surfaces exposed to moisture to prevent rusting.

- Fireproofing: In some cases, steel beams and rods are covered with fireproof material or encased in concrete to increase fire resistance.

Tools and Materials Needed:

- Steel rods (TMT bars)

- Steel beams (I-beams, H-beams, etc.)

- Bar cutting and bending machines

- Binding wire

- Welding tools (for beams)

- Concrete and formwork materials

By carefully following these steps, you can ensure that the steel rods and beams in your construction are properly installed, leading to a strong, durable, and safe building structure. If you need further details on materials or specific designs, feel free to ask!

Add comment